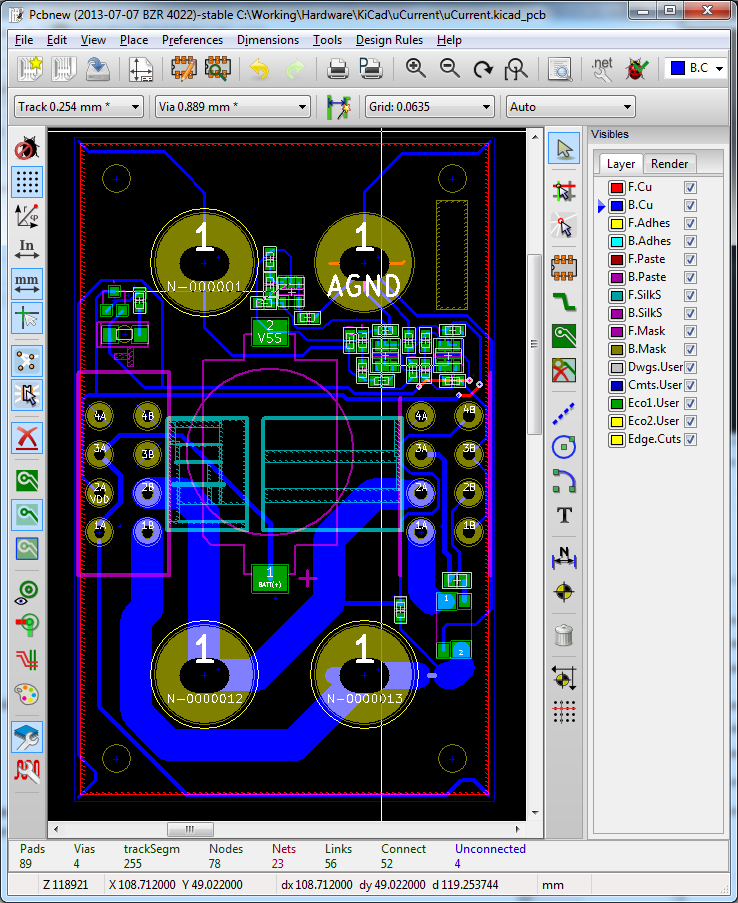

You may need to add text on your board, such as the company name. In the same way, you can do the page setting in your schematic as well. Whatever you type in this window will appear on the right bottom corner. in the title block at the right bottom corner. To do that follow these steps: We have to add the details such as the name of the board, part number and required comments, etc. Now let’s check how to write the details in these sections before generating the gerber. Also, there should be several other pieces of information in the fabrication drawing, which are marked in the image below: Now check whether you have placed all components required for manufacturing as per your design requirements. Once these are done the layout checks are complete. Later, check the schematic values, whether the components are placed correctly and the quality markings are correct in the circuit. the footprint, the component values, etc., should match the manufacturer’s part number. You need to confirm whether the bill of materials (BOM) which you have created is as per your schematic. There are three types of checklists you need to go through before generating your production files – BOM, schematic, and layout. How to generate pick and place files in KiCad.We will cover the following topics in this KiCad tutorial: So for that, we have created a checklist here. But before generating the gerber files, it is important to make sure our design is perfect with the schematics and the PCB layout. Once the routing is completed, we can export our gerber files.

We have covered how to route in KiCad in our previous article, now our design is ready for manufacturing. RLC Resonant Frequency and Impedance Calculator.

0 kommentar(er)

0 kommentar(er)